Boost Productivity & Cut Costs with Automated Pouch Packing Systems

Single Station Pouch Packing System

Up to 8 Bags Per Minute

480 Bags Per Hour

3,840 Bags Per Shift

The power of 3 employees in one compact, efficient solution—enhance productivity, reduce costs, and streamline your packaging process.

Multi Station Pouch Packing System

Up to 20 Bags Per Minute

1,200 Bags Per Hour

9,600 Bags Per Shift

The power of 8 employees in one seamless, high-speed solution—boost efficiency, cut costs, and maximize productivity.

See Our Pouch Packing Machine in Action

Get an in-depth overview of our high-efficiency pouch packaging system, from product infeed to final palletizing. This fully integrated automation line boosts throughput, reduces manual labor, and delivers consistent, high-quality packaging across food, cosmetic, and industrial applications.

Request a Quote

Increased Efficiency

Fully automated from filling to palletizing.

Versatility

Suitable for various pouch types and product forms.

Cost Savings

Reduce labor and minimize waste with precise weighing and filling.

Labor Reduction

Automating this packaging line has significantly decreased the need for manual labor by up to 75%.

System Components & Features

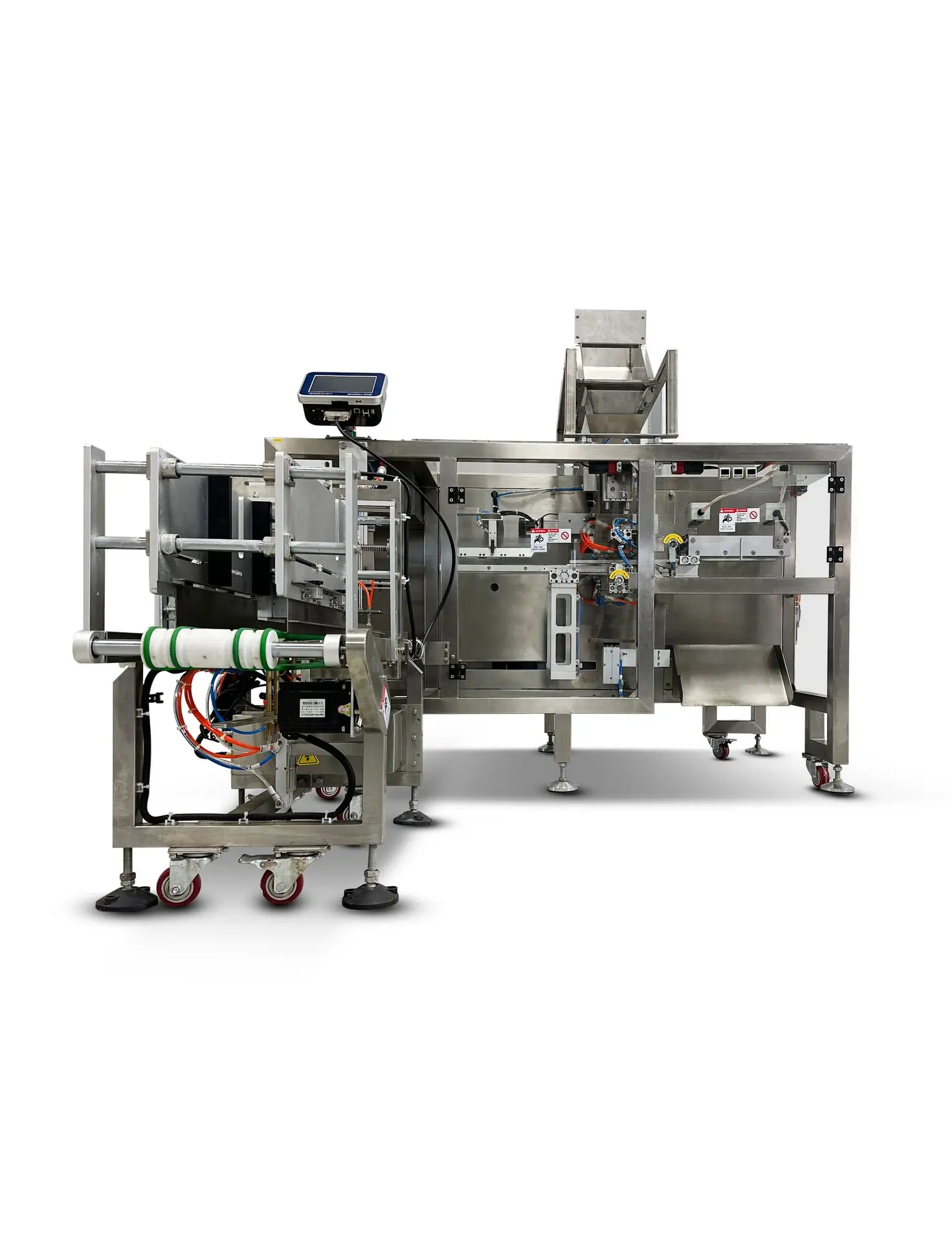

4-Station Pouch Packaging Machine

Handles quad side seal and standard zipper pouches efficiently.

Infeed Elevator with 14-Head Multihead Weigher

Delivers precise product weighing and smooth, continuous transfer.

Infeed Elevator

Automates product lifting and feeding, reducing manual labor and improving efficiency.

Stainless Steel Platform with Stairs

Provides safe, convenient access for operation and maintenance.

Exit Conveyor

Transports finished pouches efficiently to the next stage of packaging.

Check Weigher & Metal Detector

Guarantees product safety and quality control by detecting weight inconsistencies and metal contaminants.

Transfer Conveyor & Carton Erector

Streamlines secondary packaging.

Pallet Wrapper

Prepares products for shipment securely.