Flow Wrapper for Every Product

Choose Overfeed for solid items and Inverted for soft or sticky products, both built for clean, reliable seals and professional results.

Efficient Packaging with Overfeed and Inverted Flow Wrappers

Overfeed Horizontal Flow Wrappers

A horizontal flow wrapper is a packaging machine that wraps a product in film while it is carried along a horizontal conveyor belt. The film is sealed on three sides: a central seal runs along the bottom of the package, and two end seals are made at both ends of the product. This process ensures a secure and professional-looking package. The system typically uses pusher chain lugs or a conveyor belt to guide the product through the packaging process.

Overfeed Horizontal Flow Wrappers Best For:

Horizontal flow wrappers are perfect for solid, individual items like candy bars, health bars, snack foods, bath bombs, and medical items. They are especially effective for products that are stable on their bases and can be easily moved along a conveyor without damage.

Inverted Horizontal Flow Wrappers

Inverted flow wrappers work similarly to an overfeed horizontal flow wrappers but with an inverted film feed. In this setup, the product transitions from the infeed conveyor directly on top of the film before it is wrapped. This is ideal for handling delicate or fragile items. These machines usually use a conveyor belt system but can also employ a pusher chain system depending on the product’s requirements.

Inverted Horizontal Flow Wrappers Best For:

Inverted flow wrappers are particularly suited for soft, sticky, or irregular-shaped items that could be damaged or dislodged by standard pusher lugs. Commonly packaged products include tortillas, fresh produce, and other delicate items.

How Does a Flow Wrapper Work?

Product Loading

Products are placed on a conveyor and fed into the flow wrapper.

Film Feeding

A roll of packaging film is unwound and fed into the machine, where it wraps around the product.

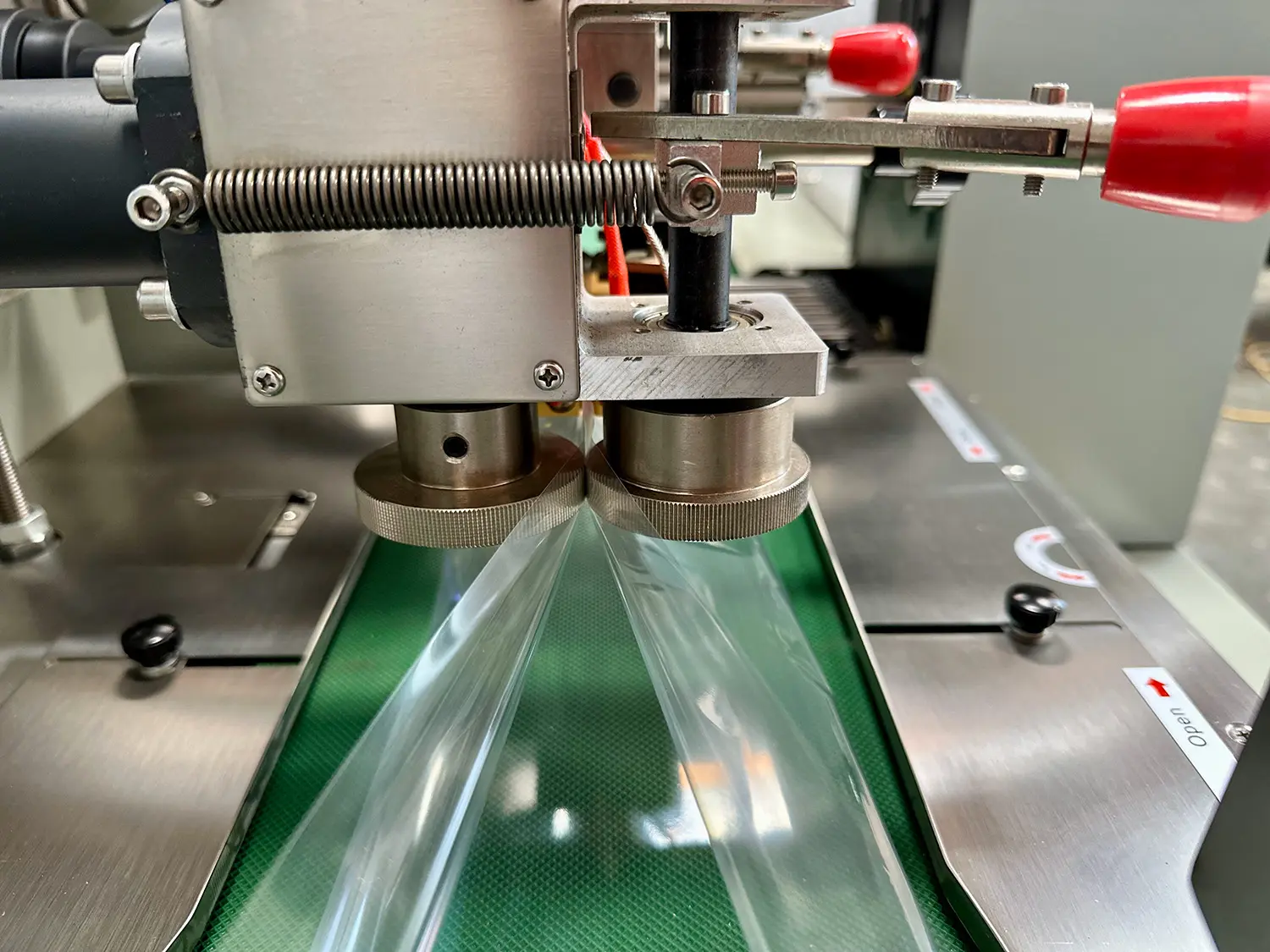

Sealing

The machine seals the film along the length of the product to create a tube, then seals and cuts the film at both ends, forming individual packages.

Finished Packaging

The wrapped products are moved out of the machine, ready for further handling or shipping.

Some Machine Specifications:

F987S

- Max Film Width: 9.84″ (250mm)

- Bag Dimensions:

Width: 1.18″ to 4.33″ (30mm - 110mm)

Length: 1.57″ to 11.02″ (40mm – 280mm) - Max Product Height: 1.57″ (40mm)

- Packaging Speed: Capable of 40-200 cycles per minute

- Max Film Roll Diameter: 12.59" (320mm)

- Machine Size: 12′ 5″ x 2′ 3″ x 4′ 9″ (3770mm x 670mm x 1450mm)

- *System specifications may change based on configuration.

F1380S

- Max Film Width: 14.56″ (370mm)

- Bag Dimensions:

Width: 2.36″ to 6.29″ (60mm - 160mm)

Length: 3.15″ to 19.68″ (80mm - 500mm) - Max Product Height: 2.75" (70mm)

- Packaging Speed: Capable of 30-225 cycles per minute

- Max Film Roll Diameter: 12.59" (320mm)

- Machine Size: 13′ 3″ x 3′ 2″ x 5′ 5″ (4000mm x 950mm x 1650mm)

- *System specifications may change based on configuration.

IF1770S

- Max Film Width: 17.71″ (450mm)

- Bag Dimensions:

Width: 1.96″ to 7.08" (50mm - 180mm)

Length: 7.08″ to 17.71″ (180mm - 450mm) - Max Product Height: 2.95" (75mm)

- Packaging Speed: Capable of 40-120 cycles per minute

- Max Film Roll Diameter: 12.59" (320mm)

- Machine Size: 12′ 11″ x 2′ 9″ x 4′ 10″ (3920mm x 820mm x 1450mm)

- *System specifications may change based on configuration.

IF2750S

- Max Film Width: 27.55″ (700mm)

- Bag Dimensions:

Width: 3.93″ to 11.02" (100mm -280mm)

Length: 7.08″ to 19.68″ (180mm - 500mm) - Max Product Height: 3.93" (100mm)

- Packaging Speed: Capable of 40-120 cycles per minute

- Max Film Roll Diameter: 12.59" (320mm)

- Machine Size: 14′ 2″ x 3′ 2″ x 4′ 11″ (4340mm x 970mm x 1500mm)

- *System specifications may change based on configuration.

Find The Perfect Flow Wrapper For Your Packaging Needs

Overfeed Horizontal Flow Wrappers:

Inverted Horizontal Flow Wrappers: