Frozen Dessert

Our specialized packaging for the ice cream and popsicle industry guarantees optimal preservation and appealing presentation. We ensure your frozen treats remain delicious and attractive, even in the most demanding conditions.

Frozen Dessert Packaging Systems for Freshness and Quality

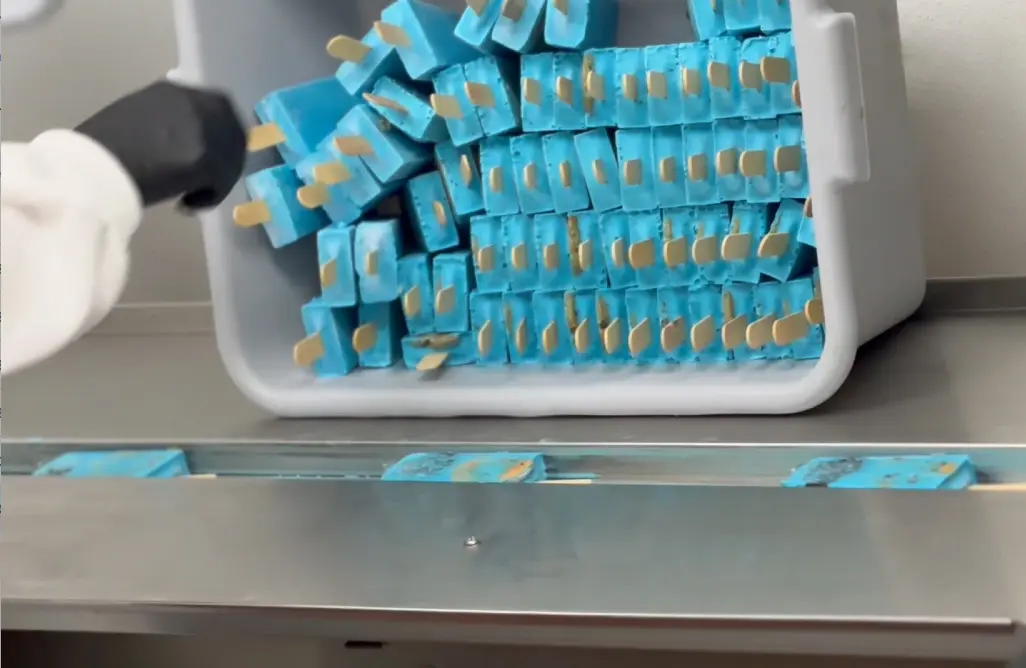

Popsicles

Popsicle loader in action, automatically separating popsicles and feeding them into the packaging line for smooth, continuous infeed.

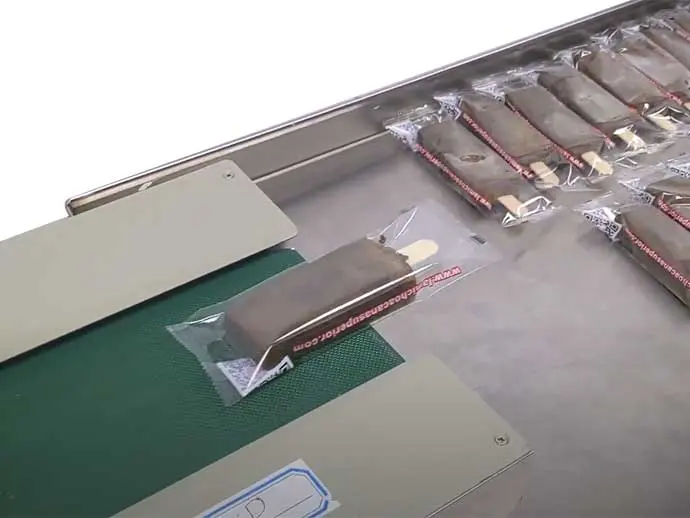

Paletas

Watch the F987S in action packing paletas, high-speed flow wrapping with consistent seals and a clean finished pack.

Preserve Freshness and Quality with Our Packaging System

Automated packaging keeps your Bakery products fresh and perfectly Automated packaging keeps your popsicles and frozen desserts fresh and securely sealed while carefully handling frozen items. It speeds up production, reduces labor costs, and helps maintain product integrity, so your frozen treats stay at their best for longer periods.

Deliver Consistent High-Quality Packaging for Every Batch

Save Time And Cost

Revolutionize your packaging with our machines designed to streamline operations, cut labor costs, and maximize productivity.

Consistent High-Quality Packaging

Protect your products and ensure they arrive to customers in perfect condition.

Print Logos, Date Codes, and Barcodes

Integrated printing capabilities allow for seamless branding and compliance, ensuring every package meets industry standards.

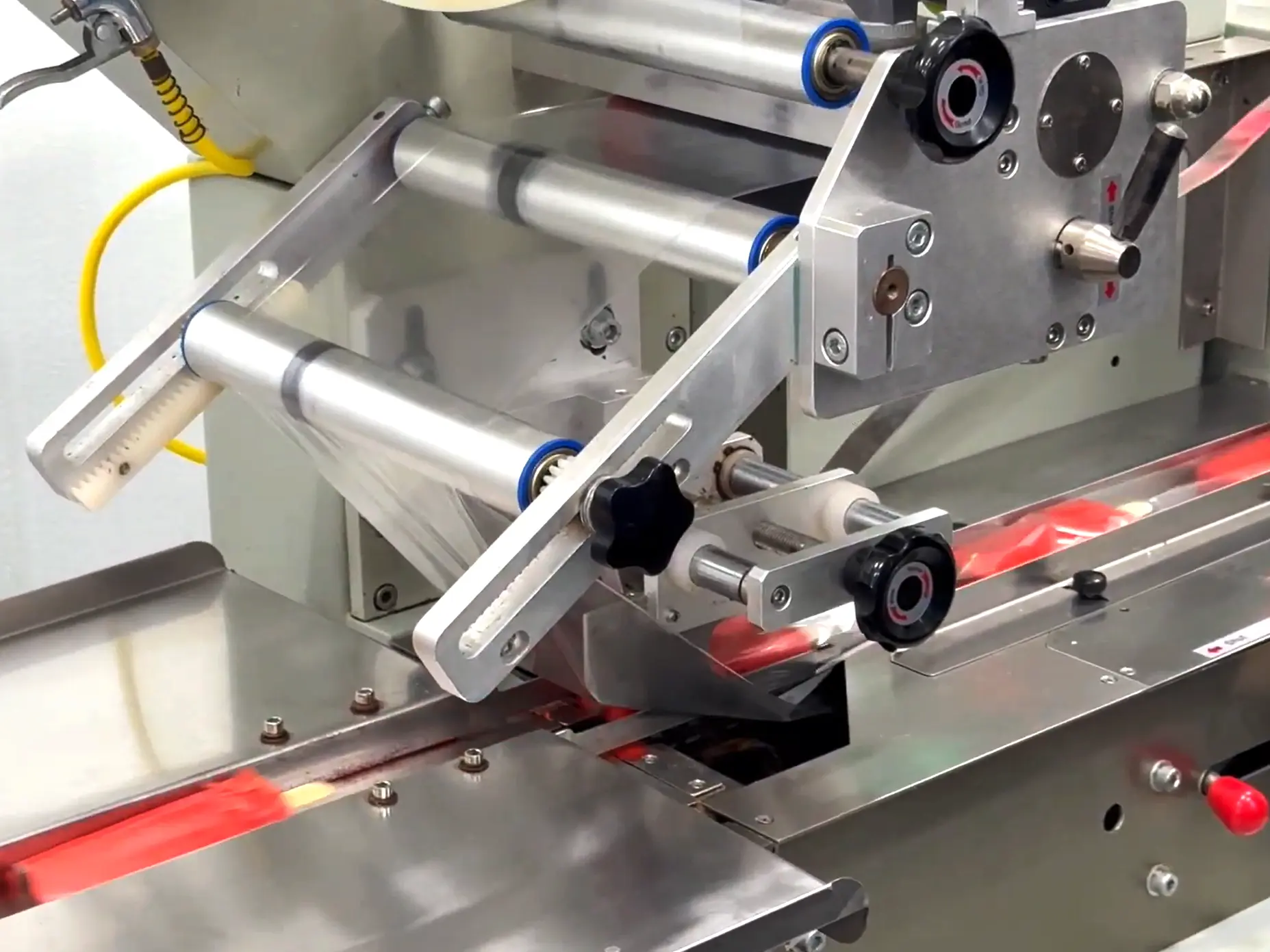

Compatible Accessories

Offering a range of compatible accessories, including popsicle feeders, digital printers, cold plates, and more.

Choose the Perfect Sealing for Your Products

No Tear Notch

The Straight Cut with No Tear Notch style features a clean, straight-cut top without any pre-cut notches for hand tearing, requiring scissors or tools to open. This design provides a stronger, more secure seal, ideal for products that need extra protection, such as food or medical items.

Single Notch

The Straight Cut Single Notch style features a clean, straight-cut top with a single pre-cut notch, allowing for easy hand tearing. This design balances convenience and security, making it ideal for products that need protection but are also meant to be opened easily.

Triple Tear Notch

The Straight Cut Triple Tear Notch style has a straight-cut top with three strategically placed tear notches for easy opening from multiple points. This design ensures convenience for the user while maintaining a secure seal, ideal for products requiring flexible access points without compromising protection.

Full Serrated Tear Notch

The Straight Cut Full Serrated Tear Notch style features a straight-cut top with a fully serrated edge for easy tearing along the entire width. This design offers a combination of secure sealing and effortless opening, perfect for products that need both protection and user-friendly access.

Choose the Perfect Printer

Ink Roller Printer

Ink Roller Printer use a roller to transfer ink for simple batch codes on packaging, offering a cost-effective solution but with lower print quality and potential for smudging. They are commonly used for printing batch numbers, expiration dates, and basic text on high-volume packaging lines.

More DetailsThermal Transfer Printer

Thermal Transfer Printers use heat to transfer ink from a ribbon onto packaging, providing high-resolution, durable prints that resist smudging and fading. They are ideal for industries requiring detailed variable data on flexible films or labels.